Explore AI Summary

Why Consider CNC Spindle Grippers?

Efficiency and productivity is the backbone of a successful manufacturing company. And as a small or medium-sized machine shop, every aspect of your production process plays a huge role in determining your profit margins. In this blog post, we’ll introduce our CNC Spindle Grippers - a game-changer in the CNC machining world. We'll dive into why these grippers are a must-have for small production runs, how they easily adjust for different part sizes, and how to quickly install and program them.

What Are the Advantages?

Run your machines unattended:

With an automatic CNC Spindle Gripper, you can save time and money by running your parts completely unattended. The CNC Spindle Gripper eliminates the need for an operator, and can be installed in only a couple of hours. The gripper will automatically pick up your stock, load it in the vise, unload the complete part, and repeat. For the first time, it's almost as easy to run 50 pieces as it is to do just one.

Simple Install and Operation:

Let's face it: full robotic system are expensive and complicated. Bringing in an actual robot almost always requires bringing in a robot integrator, and usually requires a minimum of a $50,000 budget. When we were looking to automate our own production runs, we came up with our patent-pending Air Bypass Block for our CNC Spindle Grippers to allow us to use CNC Spindle Grippers on our machines that didn't have Through-Spindle Coolant or Air. These grippers go on in a matter of three-to-four hours, or about thirty minutes with our Air Control System, which should come to market about a month from today. Not only are robots complicated and expensive to install, but they aren't very flexible. For every new part, the robot has to be retrained and the program rechecked.

Spindle Grippers, on the other hand, use the robot you already have: your CNC Vertical Milling Center. If you think about it, every CNC Machine is already a g-code driven robot, so why not use one set of code, one "robot", and one g-code interface to control it all?

Part Size Flexibility:

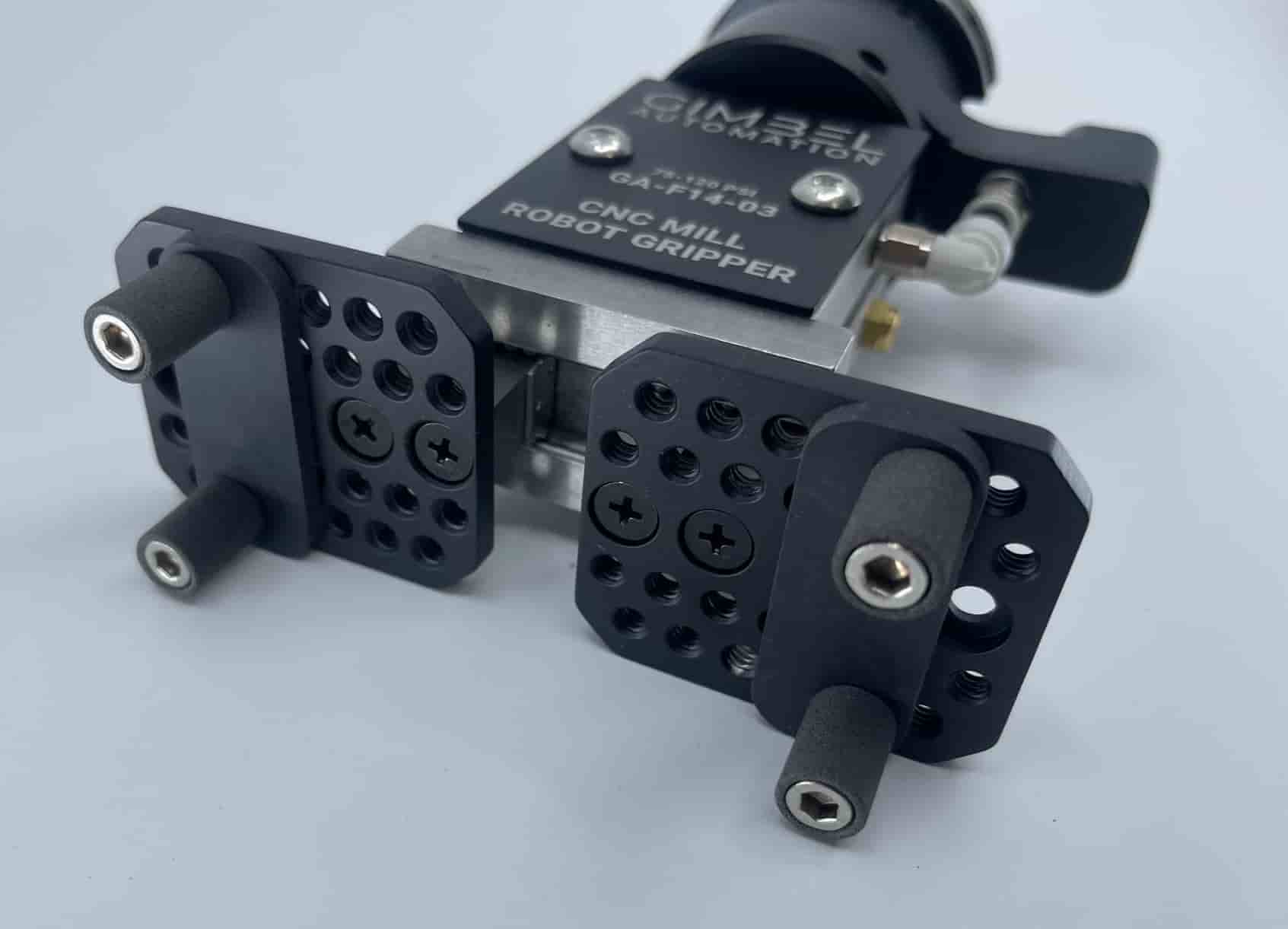

One of the most significant advantages of our CNC Spindle Gripper compared to others on the market is that you can hold almost any size square or round part thanks to our universal gripper plates. Unlike traditional grippers, which require machining or 3D printing for every new job, the CNC gripper system allows for easy adjustments in seconds! With integrated rubber pads, it can also be used to apply light preload as your pneumatic or hydraulic vise is tightened to ensure consistent and repeatable results. As you can see below, the regularly-patterned holes let you adjust the gripper for any size of part.

Held in Your Toolchanger

Our CNC Spindle Gripper Systems is versatile and will work with umbrella tool-changers or side-mount tool-changers without using up additional tool pockets. This makes it a hassle-free experience to incorporate the gripper into your existing production process, resulting in increased productivity and consistent part quality.

Revolutionize Your Production with CNC Spindle Grippers

Small to medium-sized machine shops can increase productivity, save time, and increase part quality with CNC spindle grippers. It eliminates the need for costly robots and is an economical option that can be run unattended, doubling and even tripling productivity. The universal gripper plates make it easy to hold a wide range of part sizes. The adjustments can be done in seconds without needing new grippers for every job, then it can be programmed and installed quickly. This revolutionary invention is the next step in the world of CNC machining, and we at Gimbel Automation highly recommend it to any small or medium-sized machine shop that wants to keep up with the industry's ever-increasing demand.